The 904L seamless tubing usually refers to seamless boiler, superheater, and heat exchanger tubes made from super austenitic stainless steel UNS N08904 in accordance with ASTM A213 (ASME SA-213). 904L (UNS N08904) is a high corrosion-resistant austenitic stainless steel alloy with the nominal composition 44Fe-25Ni-21Cr-Mo. It offers exceptional resistance to general and pitting corrosion, especially in sulfuric and phosphoric acid environments. The alloy is often preferred over 316L and 317L stainless steels due to its superior performance in aggressive conditions, including high-temperature chloride solutions. Common applications include chemical plants, pollution control equipment, and seawater systems.

Chemical Composition Requirements

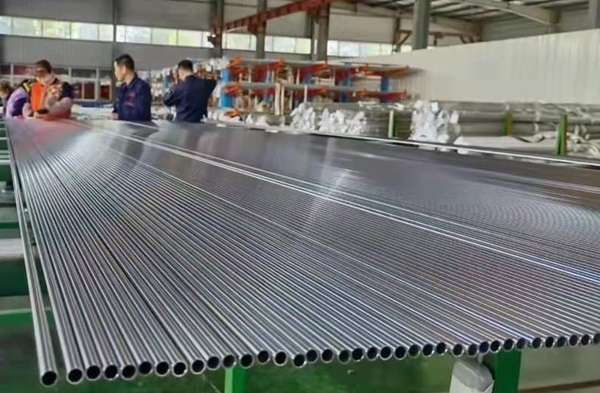

904L seamless tubes made to ASTM A213 N08904, in pickled condition.

ASTM A213 N08904 (904L) seamless tubes shall conform the following chemical requirements:

- Chromium (Cr): 19.0-23.0%

- Nickel (Ni): 23.0-28.0%

- Molybdenum (Mo): 4.0-5.0%

- Copper (Cu): 1.00-2.00%

- Manganese (Mn): 2.00% max

- Silicon (Si): 1.00% max

- Carbon (C): 0.020% max

- Sulfur (S): 0.030% max

- Phosphorus (P): 0.040% max

- Nitrogen (N): 0.10% max

Heat Treatment & Mechanical Properties

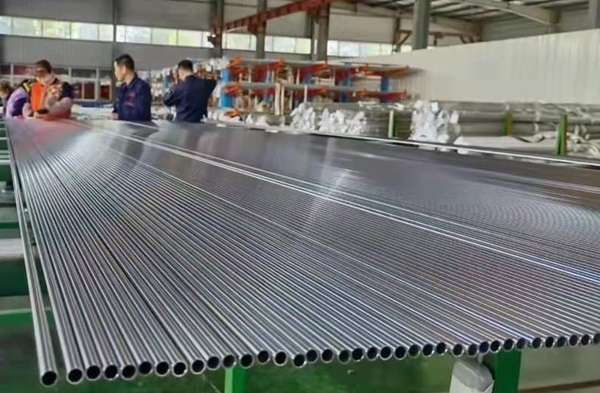

Bright annealed ASTM A213 N08904 seamless tubes, (OD)19.05mm x (WT)1.65mm x (L)3080mm, supplied to Saudi Arabia.

ASTM A213 N08904 seamless tubes shall be made by the seamless process and shall be cold finished. Final solution annealing shall be applied to the 904L seamless tubing: Heat the tube to 1100-1150°C (2000-2100°F) and then rapidly cool. This process ensures optimal corrosion resistance and mechanical properties by dissolving precipitates and relieving stresses. The mechanical properties of ASTM A213 N08904 seamless tubes are as follow:

- Tensile Strength: Minimum 71 ksi (490 MPa)

- Yield Strength: Minimum 31 ksi (215 MPa)

- Elongation: Minimum 35% in 2 inches (50 mm)

- Hardness: Typically not exceeding 90 HRB, 192 HBW, or 200 HV.

Main Applications

ASTM A213 N08904 seamless tubes (904L stainless steel seamless tubes) are high-performance austenitic stainless steel tubes, widely used across various industrial sectors:

- Chemical and Petrochemical Industry: Due to 904L’s exceptional resistance to acidic media like sulfuric and phosphoric acids, ASTM A213 N08904 seamless tubes are extensively used in the manufacture of equipment such as heat exchangers, evaporators, condensers, and pipelines for transporting corrosive liquids. These tubes are also used in the internal structures of tanks and reactors, especially in environments handling strong acids and chlorinated compounds.

- Marine Engineering: 904L seamless tubes are commonly used in heat exchanger pipelines of seawater desalination plants, due to their excellent corrosion resistance in high chloride environments, effectively resisting chloride corrosion from seawater. In marine environments, 904L seamless tubes are often used in the construction of oil platforms and subsea piping because they maintain structural stability and corrosion resistance in high salt and high humidity conditions.

904L tube bundles for a shell-and-tube heat exchanger, supplied to Italy.

- Pulp and Paper Industry: ASTM A213 N08904 seamless tubes are used in equipment for handling pulp, especially in processes involving strong acid bleach due to their resistance to chloride and acidic pulp.

- Environmental Protection: 904L seamless tubes are widely used in desulfurization equipment, particularly where high-temperature and highly corrosive gases are handled. Their high sulfuric acid corrosion resistance extends the service life of heat exchangers and condensate tubes in flue gas desulfurization towers.

- Pharmaceutical Industry: In the pharmaceutical industry, where high cleanliness and corrosion resistance are required, 904L stainless steel seamless tubes are used in equipment dealing with strong acidic substances or rigorous cleaning processes, ensuring both the purity of pharmaceuticals and the durability of production equipment.