Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

ASTM B163 UNS N04400 seamless tubes for heat exchangers and condensers are engineered from Nickel-Copper alloy UNS N04400, renowned for exceptional corrosion resistance and thermal conductivity. ASTM B163 is a standard set by ASTM International that specifies the requirements for seamless nickel and nickel alloy condenser and heat-exchanger tubes, Monel 400 is a common trade name for the nickel-copper alloy corresponding to UNS N04400. B163 UNS N04400 seamless tubes for heat exchangers and condensers typically require maximizing heat transfer efficiency and withstand higher internal pressures, hence their sizes are usually small, typically ranging from 1/8 inch[3.175mm] to 3 inches [76.2 mm] in outside diameter and below, and with minimum wall thicknesses of 0.148 inches [3.76 mm] and below.

Measurement of outside diameter for ASTM B163 UNS N04400(Monel 400)1 inch tubes, supplied to a customer in Egypt.

The chemical composition requirements for ASTM B163 UNS N04400 tubes are as follows:

The chemical composition may vary slightly depending on the specific manufacturing process used for the tubes, but the requirements listed above represent the general composition range for ASTM B163 UNS N04400 tubes.

The mechanical properties of ASTM B163 UNS N04400 tubes depend on the heat treatment condition and the dimensions of the tube. The following are the mechanical properties of Monel 400 tubes under different heat treatment conditions:

| Condition | Tensile Strength, min ksi(MPa) | Yield Strength, min ksi(MPa) | Elongation in 2in. min. % | Rockwell Hardness |

|---|---|---|---|---|

| Annealed | 70(483) | 28(193) | 35 | B75 max |

| Stress-relieved | 85(586) | 55(379) | 15 | … |

The manufacturing process for ASTM B163 UNS N04400 seamless tubes for heat exchangers and condensers involves carefully selecting high-quality Nickel-Copper alloy UNS N04400, followed by shaping the alloy into billets or hollow tubes through hot extrusion or piercing. These tubes undergo hot working processes to refine their dimensions and mechanical properties, with optional cold working for further enhancement. Heat treatment, including annealing or stress relieving. Annealing is typically used to enhance the mechanical properties and structural integrity of ASTM B163. It involves heating the tubes to a specific temperature range and maintaining them for a certain duration to ensure uniform heating, facilitating the relaxation of internal stresses and recrystallization of the metal structure to improve ductility, toughness, and uniformity. Finally, they are gradually cooled in a controlled manner. Stress relieved is generally used to alleviate residual stresses within metal components. Overall, this meticulous process guarantees that the seamless tubes meet the necessary standards for corrosion resistance, thermal conductivity, and mechanical strength, making them ideal for critical applications in heat exchangers and condensers.

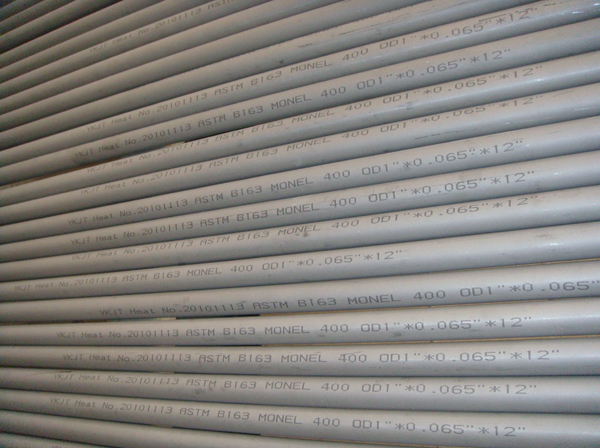

ASTM B163 UNS N04400(Monel 400)tubes, supplied to Doha, Qatar. O.D.=1inch, W.T.=0.065inch, L=12feet.

In order to ascertain the quality and assess the suitability of ASTM B163 UNS N04400 tubes for applications in condensers and heat exchangers, a series of tests is imperative. These tests include chemical analysis to verify the alloy’s composition, tensile testing to assess its mechanical strength, hardness testing to measure its resistance to deformation, and hydrostatic or nondestructive electric testing to detect defects. Additionally, intergranular corrosion testing evaluates the material’s susceptibility to certain corrosive environments, while flattening and flaring tests assess its ductility and ability to withstand deformation during installation. Dimensional inspection ensures the tubes meet specified tolerances, while surface condition inspection checks for defects that could compromise performance. Finally, macro-etch testing provides insights into the material’s structure and homogeneity. These comprehensive tests help guarantee that UNS N04400 tubes meet stringent quality and performance standards for industrial applications.

ASTM B163 UNS N04400 tubes have multiple advantages over other materials in certain applications. Monel 400 exhibits outstanding corrosion resistance to various media, including seawater, acids, alkalis, and various industrial chemicals. This corrosion resistance surpasses that of many other materials, making it particularly suitable for applications in those involving exposure to corrosive environments. It ensures longevity and reliability in harsh conditions. While maintaining high corrosion resistance, Monel 400 also maintains good mechanical strength and toughness at high temperatures, ensuring the structural integrity and reliability of components made from Monel 400. Monel 400 tubes also have relatively high thermal conductivity and compressive strength.Overall, B163 UNS N04400 tubes offer reliable performance, longevity, and corrosion resistance, making them indispensable components in heat exchangers and condensers across various industries and sectors.