Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

The seamless tubing made of ASTM B111 UNS C70600 is a typical copper-nickel tubing for use in surface condensers, evaporators, and heat exchangers. ASTM B111 C70600 is also know as “CuNi 90/10” or “copper-nickel, 10%”, indicating the nominal composition of 90% copper and 10% nickel. It usually exhibits a soft lavender or light purple metal luster, thus, is sometimes called “white copper”. ASTM B111 C70600 tubes exhibit excellent corrosion & erosion resistance, and biofouling resistance in seawater. Despite facing challenges from titanium alloys and duplex stainless steels in some cases, C70600 copper-nickel condenser tubes are still widely used in the seawater desalination industry, marine engineering, shipbuilding, power plants, and petrochemical industries due to their superior thermal conductivity and excellent workability.

ASTM B111 UNS C70600 seamless tubes, O.D.=1″, W.T.=Gauge 16 (0.065″), L=210″. Supplied to Genova, Italy.

| Element | Weight Percent, % |

|---|---|

| Pb | ≤0.05 |

| Fe | 1.0~1.8 |

| Zn | ≤1.00 |

| Mn | ≤1.00 |

| *Ni | 9.0~11.0 |

| *Cu | remainder |

| Temper | Tensile Strength min. MPa [ksi] | Yield Strength min. MPa [ksi] |

|---|---|---|

| O61 Annealed | 275 [40] | 105 [15] |

| H55 Light-Drawn | 310 [45] | 240 [35] |

ASTM B111 UNS C70600 has the following international equivalent grades: Grade BFe10-1-1 of Chinese standard; Gr. CN102 of BS 2871-2; CuNi10Fe1.6Mn (2.1972) of DIN 86019; CuNi10Fe1Mn (CW352H) of EN 12449; JIS H: C7060, CNP1; EEMUA: UNS 7060X.

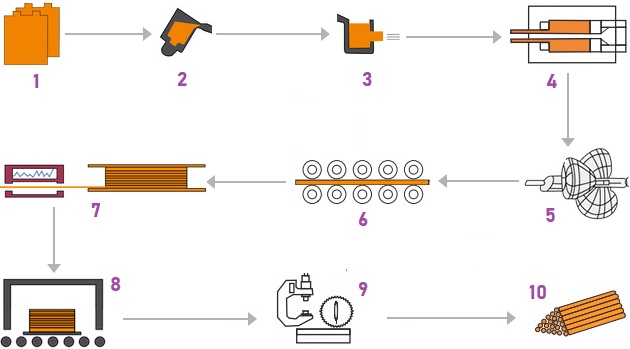

Figure-1: The production flow chart for the manufacturing of copper and copper alloy tubes. 1 – raw material preparation, 2 – melting process, 3 – ingot casting, 4 – extruding, 5 – drawing or rolling, 6 – finishing, 7 – hydrostatic test & eddy current test, 8 – bright annealing, 9 – final inspection, 10 – packing & stocking.

At the discretion of the purchaser, ASTM B111 C70600 (CuNi 90/10) seamless tubing may be supplied in annealed temper (O61) or light-drawn temper (H55). A “temper” of the copper or copper alloy tube refers to the metallurgical structure and properties of the tube resulting from thermal or mechanical processing treatment. Starting from the melting and ingot casting process, the cupronickel tubes are typically produced from tube shells made by extruding or piercing copper billets. The seamless tubing may be finally furnished with the bright annealing treatment, which is intended to soften and to increase the ductility and toughness of the CuNi 90/10 tubing. It results in the annealed temper O61. If the tubing is subsequently slightly cold worked (light-drawing), a stronger temper H55 is attained.

ASTM B111 C70600 seamless tubes, Φ38.1mm x 2.11mm x 3600mm, supplied to an African client in Luanda, Angola.

Similar to other copper and copper alloy tubes, the following inspection and tests shall be conducted on ASTM B111 UNS C70600 seamless condenser tubes: grain size determination, expansion test, flattening test, residual stress test (optional), eddy current test, hydrostatic test, dimensional inspection (diameter, wall thickness, length, end cut), as well as visual examination.