Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

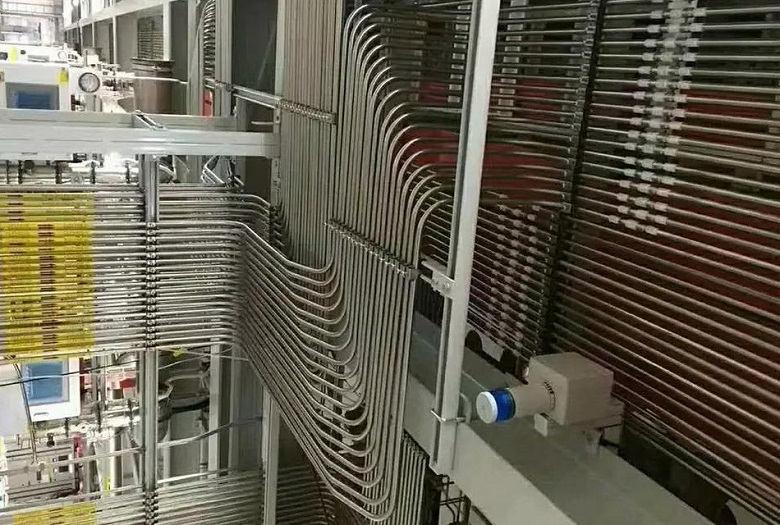

The layout of stainless steel instrument tubing in a chemical plant in Doha, Qatar.

Instrumentation tubing, also known as instrument tubing, refers to specialized tubing designed and manufactured for use in instrumentation systems. These systems are utilized across various industries to measure, monitor, and control parameters such as pressure, temperature, flow rate, level, and composition in industrial processes. Instrumentation tubing serves as the conduit for transmitting fluids or gases to and from instruments, sensors, valves, and control devices within these systems. SJZ Metalsin has been supplying instrument tubing for a wide range of industries and applications, including chemical process, oil and gas, pharmaceuticals, food and beverage, water treatment, power generation and more.

ASTM A269 is the standard specification that covers a series of austenitic stainless steel grades of nominal-wall-thickness seamless or welded tubing for general corrosion-resisting and low- or high-temperature service. The tubing sizes and thicknesses furnished to this specification are 1/4″ [6.4 mm] in inside diameter and larger and 0.020″ [0.51 mm] in nominal wall thickness and heavier. Instrumentation systems require precise and accurate measurement and control to ensure optimal performance and safety in industrial processes. The tubing used in these systems must maintain integrity and reliability to prevent leaks, contamination, or inaccuracies in measurements.

ASTM A269 TP316/316L dual-certified seamless tubing, supplied to Baghdad, Iraq. OD19.05mm x WT1.65mm x L=3.5m, straight length, bright annealed, with protective, plastic end caps.

In many industrial environments, particularly in chemical processing, petrochemical, and offshore applications, instrumentation tubing is exposed to corrosive substances, high pressures, and extreme temperatures. A series of ASTM A269-compliant austenitic stainless steel tubing are used for such demanding conditions due to their excellent corrosion resistance. These stainless steel grades typically include TP304/ TP304L, TP316/ TP316L, TP317, TP321, TP347, S31254, N08367, N08925, N08926, and N08904, etc. Instrumentation tubing used in industries such as pharmaceuticals, biotechnology, and food processing must adhere to strict cleanliness and hygiene standards to prevent contamination of sensitive processes and products. ASTM A269 tubing’s smooth surface finish facilitates easy cleaning and sterilization, minimizing the risk of contamination.

The surface finish of instrumentation tubing is crucial for ensuring smooth fluid flow, minimizing turbulence, and reducing the risk of particle entrapment or contamination. ASTM A269 tubing typically has a smooth, defect-free surface finish, ranging from annealed and bright annealed to polished or electropolished, depending on the application requirements. Instrumentation tubing must be compatible with various instrumentation components, including fittings, connectors, valves, and instruments such as pressure gauges, temperature sensors, flow meters, and analytical instruments. Flexible compatibility ensures proper sealing, secure connections, and accurate measurement and control.