Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

ASTM B622 is a standard specification for seamless nickel and nickel-cobalt alloy pipe and tube. UNS N10665 is a grade specified within this standard. UNS N10665 is also known as Hastelloy B2, which is a nickel-molybdenum alloy with excellent resistance to reducing environments like hydrogen chloride gas, sulfuric, acetic, and phosphoric acids. This alloy is particularly resistant to stress-corrosion cracking and pitting. ASTM B622 UNS N10665 seamless tube includes exceptional resistance to stress corrosion cracking, pitting, and crevice corrosion, it’s commonly used in chemical processing, pharmaceutical, and pollution control equipment due to its corrosion resistance properties.

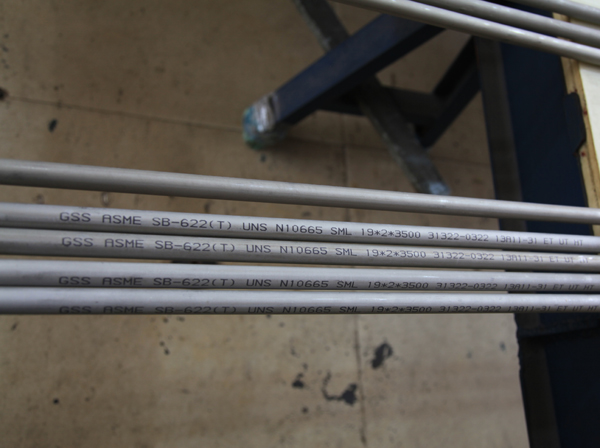

ASTM B622 UNS N10665(Hastelloy B-2) seamless tubes, O.D.=19mm, W.T.=2mm, L=3500mm, supplied to Brussels, Belgium.

Chemical composition requirements for ASTM B622 UNS N10665 seamless tubes:

The mechanical properties of ASTM B622 UNS N10665 seamless tubes typically meet the following requirements

Hastelloy B-2(ASTM B622 UNS N10665)tubes, O.D.=19mm, W.T.=2mm, L=3500mm, supplied to Rio de Janeiro, Brazil.

UNS N10665 seamless tubes (Hastelloy B2) exhibit numerous significant characteristics compared to other nickel-based alloys. UNS N10665 demonstrates outstanding corrosion resistance to various corrosive environments, including reducing acids such as hydrochloric acid, sulfuric acid, and phosphoric acid. Its corrosion resistance makes it suitable for corrosive chemical processing applications. Additionally, it boasts excellent resistance to stress corrosion cracking, making it particularly suitable for applications exposed to corrosive environments under tensile stress. UNS N10665 also possesses good wear resistance, making it an ideal choice for applications requiring durability against wear. The alloy maintains chemical stability even at high temperatures, thus suitable for high-temperature applications. With its low carbon content, UNS N10665 helps minimize the formation of carbide precipitation and sensitization during welding processes. This characteristic enhances its resistance to intergranular corrosion and ensures consistent performance in welded structures.