Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

ASTM A213 TP304H and TP316H are the “H Grades” of austenitic stainless steels designed for high-temperature applications. The letter H indicates its higher carbon content as well as the high-temperature service. Seamless tubes made of ASTM A213 TP304H (UNS S30409) and TP316H (UNS 31609) exhibit much better creep strength and creep-rupture strength at elevated temperatures, thus, are widely used for the fabrication of high-temperature heat exchangers, superheaters, reheaters, and boilers.

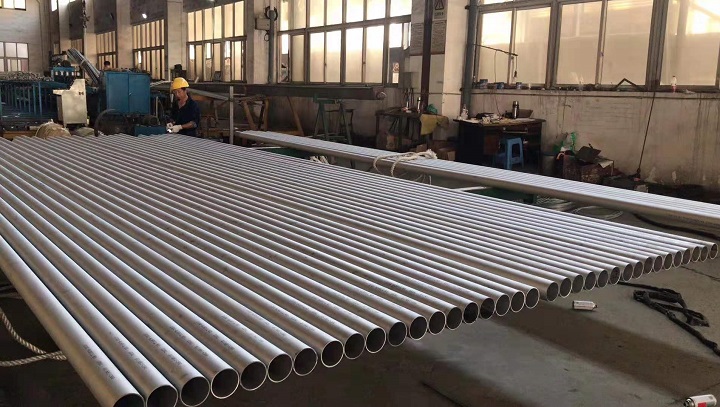

ASTM A213 TP304H seamless heat exchanger tubes, Φ31.75mm x WT1.65mm x L3683mm, supplied to Azerbaijan.

ASTM A213 TP304H and TP316H both have a higher carbon content (0.04% to 0.10%) than traditional TP304L and TP316L stainless steel, respectively. In TP304H and TP316H, the increase in carbon content (0.04% to 0.10%) leads to grain growth during heat treatment. This high carbon content helps enhance the material’s strength and creep resistance at high temperatures, but it also results in larger grain size. The coarser grain structure reduces the number of grain boundaries, thereby decreasing the possibility of dislocation movement and grain boundary sliding, which are the main mechanisms of creep deformation at high temperatures. In conclusion, the higher carbon content can lead to a coarser grain structure, which is actually beneficial for creep strength at high temperatures.

| Element | TP304H % | TP316H % |

|---|---|---|

| C | 0.04~0.10 | 0.04~0.10 |

| Mn | ≤2.00 | ≤2.00 |

| P | ≤0.045 | ≤0.045 |

| S | ≤0.030 | ≤0.030 |

| Si | ≤1.00 | ≤1.00 |

| Cr | 18.0~20.0 | 16.0~18.0 |

| Ni | 8.0~11.0 | 11.0~14.0 |

| Mo | - | 2.0~3.0 |

| Tensile & Hardness Requirements | TP304H |

|---|---|

| Tensile Strength min. MPa [ksi] | 515 [75] |

| Yield Strength min. MPa [ksi] | 205 [30] |

| Elongation in 2", min. % | 35 |

| Hardness, max. | 192 HBW 200 HV 90 HRB |

| Tensile & Hardness Requirements | TP316H |

|---|---|

| Tensile Strength min. MPa [ksi] | 515 [75] |

| Yield Strength min. MPa [ksi] | 205 [30] |

| Elongation in 2", min. % | 35 |

| Hardness, max. | 192 HBW 200 HV 90 HRB |

ASTM A213 TP316H tailor-made seamless tubes in serpentine shape for a power plant superheater.

According to ASME Boiler and Pressure Vessel Codes and ASME B31 Codes, the maximum applicable temperature for ASTM A213 TP304H is 1200°F [649°C], compared with that of 800°F [427°C] for TP304L. The maximum applicable temperature for ASTM A213 TP316H is also 1200°F [649°C], compared with that of 850°F [454°C] for TP316L.

The low-carbon variants ASTM A213 TP304L and TP316L stainless steels typically have finer grain structures because of their lower carbon content (usually restricted to below 0.035%) and sometimes further grain refinement through cold working. Fine-grained structures generally offer better overall performance, such as higher toughness and improved corrosion resistance, but may not match the strength and creep resistance of TP304H and TP316H at high temperatures. The coarse-grained structure of TP304H or TP316H stainless steel is optimized for its performance in high-temperature applications, particularly when increased creep resistance and high-temperature strength are required. However, this coarser grain structure may adversely affect other properties of the material, such as toughness and corrosion resistance.

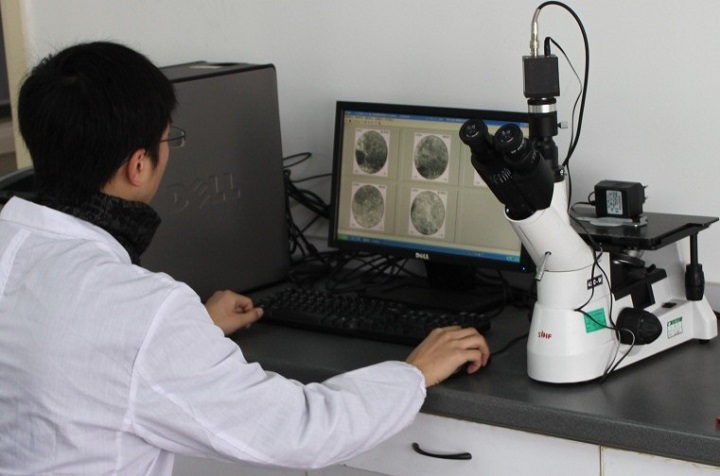

The grain size determination of the H grade stainless steel according to ASTM E112.

The ASTM A213 TP304H and TP316H seamless tubes shall be furnished with the solution treatment. This solution heat treatment process aims to preserve the corrosion resistance of the TP304H & TP316H tubes while optimizing its mechanical properties through the dissolution of carbon and other alloying elements. This process is crucial for ensuring the material’s performance at high temperatures, especially in cases where improved creep resistance and high-temperature strength are required.

In addition to other inspections and tests specified by ASTM A213, the metallographic structure of the TP304H or TP316H tubes shall be inspected in accordance with ASTM E112 to determine the average grain size, which shall be No.7 or coarser.