Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

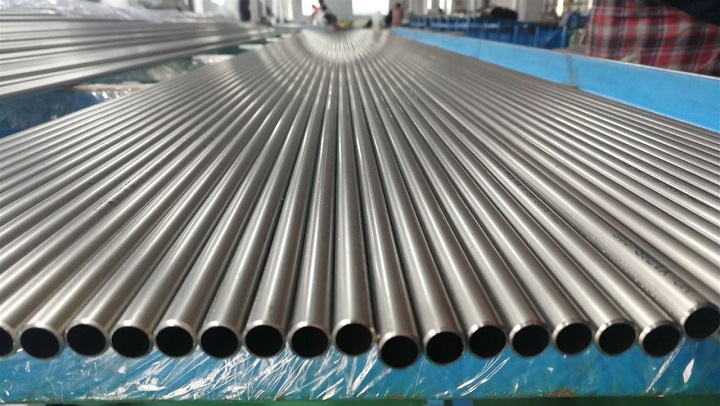

A heat exchanger made of ASTM A213 TP304 seamless tubes.

SJZ Metalsin supplies a series of seamless austenitic stainless steel boiler, superheater and heat exchanger tubes in the material grades of ASTM A213 TP304, TP304L, TP316, and TP316L. The tubing sizes usually are 1/8″ [3.2 mm] in inside diameter to 5″ [127 mm] in outside diameter. They may be furnished in minimum wall thickness or average wall thickness. If minimum wall thickness is specified, generally it shall fall within the range from 0.015″ [0.4 mm] to 0.500″ [12.7 mm]. If average wall thickness is specified, the permissible variations (tolerances) shall be ±10% of the specified average wall thickness for cold-formed tubes or ±12.5% of the specified average wall thickness for hot-formed tubes. ASTM A213 TP304/304L and TP316/316L seamless tubes are frequently employed in industries such as chemical processing, petroleum, pharmaceuticals, and food processing. Specific applications include but are not limited to oil and gas pipelines, chemical processing equipment, boilers, heat exchangers, condensers, and medical devices for fluid transfer. Due to its high strength, corrosion resistance, and ability to withstand high temperatures, they find widespread use in various harsh conditions.

“TP” stands for “Type”. Type 304 stainless steel, designated as UNS S30400, is the most basic and most commonly used austenitic stainless steel grade. TP304 stainless steel has the famous 18Cr-8Ni nominal composition. It is almost the ancestor of the austenitic stainless steel family. TP304 stainless steel is in the middle range of corrosion resistance provided by stainless steels. It resists most oxidizing acids, many sterilizing solutions, most organic chemicals and dyestuffs, and a wide range of inorganic chemicals. TP304L, designated as UNS S30403, is a modified version of TP304 with less than 0.035% carbon content. The lower-carbon grade can avoid sensitization during the relatively brief exposure of welding. TP304L has been established to prevent intergranular corrosion and to improve the corrosion resistance in welding structures.

ASTM A213 TP316L seamless tubes, Φ38.1mm x 2.11mm x 6.096m, supplied to Czech.

TP316 stainless steel, designated as UNS S31600, has similar chromium and nickel content to TP304. Specifically, the addition of molybdenum provides pitting resistance in phosphoric and acetic acids and dilute chloride solutions, as well as corrosion resistance in sulfurous acid. TP316 is a bit costly than TP304 but it provides better corrosion resistance. TP316L, designated as UNS 31603, is also treated as the low-carbon variation of TP316. It exhibits improved resistance to sensitization due to its lower carbon content, making it more suitable for applications where welding is involved.

| Element | TP304 | TP304L |

|---|---|---|

| C(%) | ≤0.08 | ≤0.035 |

| Mn(%) | ≤2.00 | ≤2.00 |

| P(%) | ≤0.045 | ≤0.045 |

| S(%) | ≤0.030 | ≤0.030 |

| Si(%) | ≤1.00 | ≤1.00 |

| Cr(%) | 18.0-20.0 | 18.0-20.0 |

| Ni(%) | 8.0-11.0 | 8.0-12.0 |

| Element | TP316 | TP316L |

|---|---|---|

| C(%) | ≤0.08 | ≤0.035 |

| Mn(%) | ≤2.00 | ≤2.00 |

| S(%) | ≤0.045 | ≤0.045 |

| P(%) | ≤0.030 | ≤0.030 |

| Si(%) | ≤1.00 | ≤1.00 |

| Cr(%) | 16.0-18.0 | 16.0-18.0 |

| Ni(%) | 10.0-14.0 | 10.0-14.0 |

| Mo(%) | 2.00-3.00 | 2.00-3.00 |

| Tensile & Hardness | TP304 | TP304L |

|---|---|---|

| Tensile Strength min. MPa [ksi] | 515[75] | 485[70] |

| Yield Strength min. MPa [ksi] | 205[30] | 170[25] |

| Elongation in 2" min. % | 35 | 35 |

| Brinell Hardness max. HBW | 192 | 192 |

| Vickers Hardness max. HV | 200 | 200 |

| Rockwell Hardness max. HRB | 90 | 90 |

| Tensile & Hardness | TP316 | TP316L |

|---|---|---|

| Tensile Strength min. MPa [ksi] | 515[75] | 485[70] |

| Yield Strength min. MPa [ksi] | 205[30] | 170[25] |

| Elongation in 2" min. % | 35 | 35 |

| Brinell Hardness max. HBW | 192 | 192 |

| Vickers Hardness max. HV | 200 | 200 |

| Rockwell Hardness max. HRB | 90 | 90 |

Bright annealing furnace for ASTM A213 seamless tubes, Wuxi, Jiangsu province, China.

The seamless tubes made of ASTM A213 TP304/304L, TP316/316L shall be produced by the seamless process and shall be either hot finished or cold finished. They shall be furnished with the solution treatment, in which the tubes are heated to a minimum temperature of 1040°C [1900°F], and held a sufficient time for full austenitization. Subsequently rapid cooling in water will complete the heat treatment process. Compared to the instrument tubing specified in ASTM A269, seamless tubes made in accordance with ASTM A213 are classified as “pressure tubing“, which commonly involves external heat applications, as in boilers and superheaters. The tubes may be furnished in pickled or bright annealed condition.