Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

SJZ Metalsin supplies ASTM A213 TP347 and TP347H seamless tubes for heat exchangers, boilers and superheaters. As a modified version of the classic 304 stainless steel, niobium is added to oppose chromium carbide precipitation, which means to stabilize the carbon in TP347 stainless steel. The niobium added has significant importance:

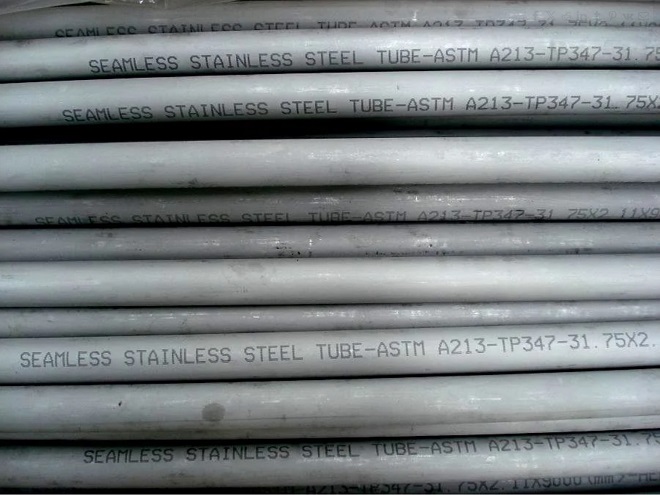

ASTM A213 TP347 seamless tubes, O.D.=31.75mm, W.T.=2.11mm, L=9510mm.

Similar to TP304H & TP316H, TP347H is the “H Grade” of austenitic stainless steel TP347. ASTM A213 TP347 typically contains a maximum of 0.08% carbon, while TP347H contains higher carbon content, typically ranging between 0.04% to 0.10%. The higher carbon content in TP347H contributes to improved creep resistance at elevated temperatures. Creep refers to the tendency of materials to deform slowly over time when subjected to sustained mechanical stress at high temperatures. The higher carbon content in TP347H enhances its creep resistance, allowing it to withstand higher loads and temperatures over extended periods without significant deformation. While higher carbon content can increase the risk of sensitization and intergranular corrosion, proper heat treatment and welding procedures can mitigate these issues. Post-weld heat treatment (PWHT) is often required for TP347H to minimize sensitization and restore corrosion resistance.

| Element | TP347 % | TP347H % |

|---|---|---|

| C | ≤0.08 | 0.04~0.10 |

| Mn | ≤2.00 | ≤2.00 |

| P | ≤0.045 | ≤0.045 |

| S | ≤0.030 | ≤0.030 |

| Si | ≤1.00 | ≤1.00 |

| Cr | 17.0~20.0 | 17.0~19.0 |

| Ni | 9.0~13.0 | 9.0~13.0 |

| Nb | 10 x C~1.10 | 8 x C~1.10 |

ASTM A213 TP347H U-type seamless tubes for the fabrication of a superheater, supplied to Milan, Italy.

| Tensile & Hardness Requirements | TP347 |

|---|---|

| Tensile Strength min. MPa [ksi] | 515 [75] |

| Yield Strength min. MPa [ksi] | 205 [30] |

| Elongation in 2", min. % | 35 |

| Hardness, max. | 192 HBW 200 HV 90 HRB |

| Tensile & Hardness Requirements | TP347H |

|---|---|

| Tensile Strength min. MPa [ksi] | 515 [75] |

| Yield Strength min. MPa [ksi] | 205 [30] |

| Elongation in 2", min. % | 35 |

| Hardness, max. | 192 HBW 200 HV 90 HRB |

Seamless tubes made of ASTM A213 TP347 and TP347H shall be furnished with the solution heat treatment, in which the austenitic stainless steel tubes are heated to a minimum temperature and held for a sufficient prolonged time to dissolve all the carbides in the microstructure. Then, these tubes are rapidly cooled in cold water. The minimum solutioning temperatures for ASTM A213 TP347, hot-rolled TP347H, and cold-drawn TP347H are 1900°F [1040°C], 1925°F [1050°C], and 2000°F [1100°C], respectively.