Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

ASTM B423 UNS N08825, also known as Alloy 825 or Incoloy 825, is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. The Incoloy 825 seamless tube provides excellent resistance to various corrosive environments, including those containing sulfuric and phosphoric acids, as well as resistance to chloride-ion stress-corrosion cracking, pitting, and crevice corrosion. Commonly used in chemical equipment, marine engineering, and oil and gas extraction.

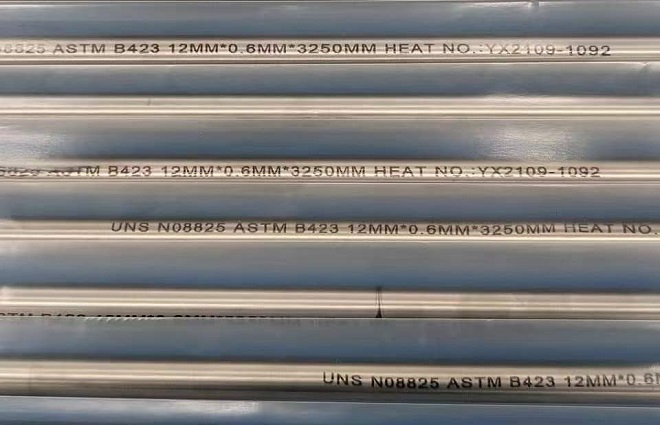

ASTM B423 UNS N08825(Incoloy 825) seamless tubes, O.D.=12mm, W.T.=0.6mm, L=3250mm, supplied to Germany.

Chemical composition requirements for ASTM B423 UNS N08825(Incoloy 825) seamless tubes:

The mechanical properties of ASTM B423 UNS N08825(Incoloy 825) seamless tubes typically meet the following requirements:

| Condition | T.S(MPa) | Y.S(MPa) | EL.(%) |

|---|---|---|---|

| hot-finished annealed | 75[517] | 25[172] | 30 |

| cold-worked annealed | 85[586] | 35[241] | 30 |

| hot forming quality | No required | ||

*T.S = tensile strength, Y.S=yield strength, EL=elongation.

ASTM B423 UNS N08825 (Incoloy 825) seamless tubes are extensively used in a variety of industrial fields due to their excellent corrosion resistance and mechanical properties. In the chemical and petrochemical industries, they handle and store corrosive chemicals such as strong acids and alkalis. In marine engineering, these tubes are employed in seawater cooling systems, offshore platforms, and other submerged structures due to their resistance to chloride-induced corrosion. In the oil and gas industry, they are used in offshore drilling platforms, oil and gas wells, and refineries for sour gas and sulfide-containing media. In the nuclear industry, they handle radioactive waste liquids and other highly corrosive media. They are also used in pollution control equipment, such as flue gas desulfurization units and acidic waste gas treatment systems. In the power industry, Incoloy 825 tubes are found in coal-fired power plant flue gas systems and geothermal power generation. Additionally, they are employed in other high-temperature and high-corrosion environments, including high-temperature heat exchangers and industrial furnace pipelines. Incoloy 825 heat exchanger seamless tubes are best suited for media containing chlorides, sulfuric acid, phosphoric acid, nitric acid, and other corrosive media, as well as high-temperature heat exchange applications. Its excellent resistance to pitting and crevice corrosion makes it an ideal choice for these harsh environments.

Incoloy 825 is a Ni-Fe-Cr-Mo-Cu alloy, where each element contributes specifically to its properties. Nickel (38.0% – 46.0%) is the primary component, providing excellent oxidation and corrosion resistance, particularly in reducing environments, and enhancing mechanical strength and toughness at high temperatures. Iron (balance) offers structural stability and strength, complementing the mechanical performance and high-temperature resistance while reducing costs. Chromium (19.5% – 23.5%) significantly enhances oxidation and corrosion resistance, forming a protective chromium oxide layer on the alloy’s surface. Molybdenum (2.5% – 3.5%) boosts resistance to reducing acids like sulfuric and phosphoric acids, and improves pitting and crevice corrosion resistance in chloride environments. Copper (1.5% – 3.0%) further improves resistance to reducing acids, especially sulfuric and phosphoric acids. Titanium (0.6% – 1.2%) reduces intergranular corrosion by forming carbides with carbon, enhancing high-temperature strength and stability. Manganese (up to 1.0%) improves oxidation and corrosion resistance, particularly at high temperatures, and increases toughness. Low carbon content (up to 0.05%) minimizes carbide precipitation at grain boundaries, reducing intergranular corrosion risk. Silicon (up to 0.5%) enhances oxidation resistance and high-temperature corrosion resistance. Sulfur (up to 0.03%) is kept minimal to avoid hot brittleness and maintain corrosion resistance. Together, these elements synergistically endow Incoloy 825 with outstanding comprehensive properties, making it perform exceptionally well in harsh environments, including high temperatures, strong corrosive conditions, and chloride-containing environments.

Hydraulic test of ASTM B423 UNS N08825(Incoloy 825) seamless tube.

ASTM B423 UNS N08825 (Incoloy 825) seamless tubes undergo rigorous testing, including hydrostatic and nondestructive electrical testing, to ensure their quality and integrity. Hydrostatic testing involves filling the tube with water, sealing it, and pressurizing it to 1.5 times its maximum working pressure to check for leaks and strength. Nondestructive electrical testing methods, such as eddy current testing (ECT), magnetic flux leakage (MFL), and ultrasonic testing (UT), are used to detect surface and subsurface defects without damaging the tube. These tests ensure that the tubes are reliable and safe for use in demanding industrial applications.