Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

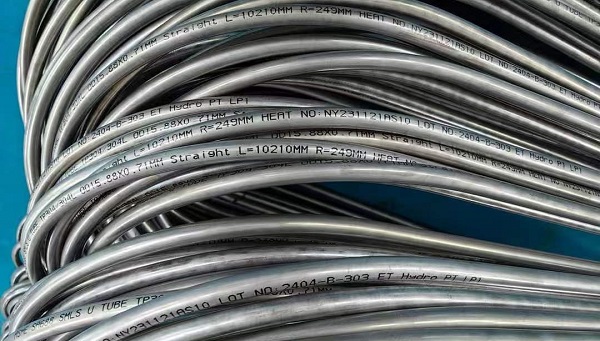

ASTM A688 TP304L seamless U-tubes for feedwater heaters, supplied to Sydney, Australia.

Metalsin Tech supplies seamless and welded austenitic stainless steel feedwater heater tubes, which are manufactured in accordance with ASTM A688. These tubes may be furnished in straight length or be bent into the form of U-tubes for application in tubular feedwater heaters. The tubing sizes covered shall be 5/8″ to 1″ [15.9 mm to 25.4 mm] inclusive outside diameter, and average or minimum wall thicknesses of 0.028″ [0.7 mm] and heavier.

A feedwater heater, functioning as a heat exchanger in power plants, heats the boiler feedwater using steam before it enters the boiler, which enhances energy efficiency by reducing the fuel needed to reach boiling point, lessens the likelihood of boiler scaling, improves fuel economy due to lower fuel consumption, and decreases emissions of pollutants, all contributing to a more cost-effective and environmentally friendly operation of steam generating facilities. Feedwater heaters are categorized into open and closed types, with open heaters using extracted steam from turbines to directly condense and transfer heat to the feedwater, while closed heaters employ a secondary fluid, typically heated feedwater from the boiler, for heat transfer; both types can have multiple stages that progressively increase the feedwater temperature, named according to their position in the steam cycle, such as low-pressure (stage) feedwater heaters or high-pressure (stage) feedwater heaters.

ASTM A688 TP304/304L dual-certified U-tubes, (OD)15.88mm x (WT)0.71mm x (Straight Length)10210mm, Radius of U bend =249mm, supplied to Ho Chi Minh city, Vietnam.

Seamless or welded tubes made to ASTM A688 are essential in feedwater heaters. These tubes serve as heat exchanger elements, with feedwater flowing inside while steam condenses outside, transferring heat. Either in straight length or U-bend, ASTM A688 seamless or welded tubes can be made from a wide variety of austenitic stainless steels including Grade 304, 304L, 316, 316L, XM-29 (S24000), 304N, 316N, 304LN, 316LN, N08367, Alloy 800 (N08800), Alloy 800H (N08810), N08811, N08926, S31254 (254SMO), S32654. These austenitic stainless steels have excellent corrosion resistance, high temperature strength, and good ability to maintain structural integrity under pressure, ensuring reliable operation, efficient heat transfer, and simplified fabrication while reducing maintenance and lifecycle costs.

ASTM A688 stainless steel seamless tubing for feedwater heaters shall be supplied from a cold finishing process. Hot finishing as the final sizing process is not allowed. ASTM A688 stainless steel welded tubing shall be made from flat-rolled steel by an automatic welding process with no addition of filler metal. Subsequent to welding and prior to final heat treatment, the tubes shall be cold worked either in both the weld and base metal to get precise diameter and wall thickness. Many surface contaminants such as copper, lead, mercury, zinc, chloride, or sulfur may have detrimental effects on high temperature properties or corrosion resistance of the tubing, hence shall be minimized or avoided. All tubes shall be carefully cleaned and dried prior to heat treatment.

The solution-annealing heat treatment for austenitic stainless steel tubes by the online resistance-heating method.

All finished straight tubing or straight tubing for U-bending shall be furnished in the solution-annealed condition. The solution-annealing heat treatment consists of heating the tubing to a minimum temperature (varying for different stainless steels), holding for sufficient long time until full autenitization, followed by a rapid cooling to below 700°F [370°C]. When applied to feedwater heaters, the ASTM A688 tubes are usually supplied as U tubes, which have been subjected to a bending operation. The solution annealing shall be applied to the U-bend area plus approximately 6″ [152.4 mm] of each leg beyond the tangent point of the U-bend. This process may be performed in a furnace or by the online resistance-heating device.

Visual examination, dimensional inspection, tensile test, hardness test, reverse bend test (for welded tubing only), flattening test, flange test (for welded tubing only), flaring test (for seamless tubing only), pressure test, grain size determination, intergranular corrosion test, non-destructive test (PT, ET, UT).