Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

ASTM A789 is a standard specification for seamless and welded ferritic/austenitic stainless steel tubing, commonly known as duplex stainless steel. UNS S31803 and S32205 are two very commonly used grades under this specification. These tubes, either furnished in average wall thickness or minimum wall thickness, are manufactured for services requiring general corrosion resistance at temperatures usually no greater than 600°F [315°C], with particular emphasis on resistance to stress corrosion cracking. They are susceptible to embrittlement if used for prolonged periods at elevated temperatures. Both ASTM A789 S31803 and S32205 are standard duplex stainless steel grades that have a mixed microstructure of approximately 50% ferrite and 50% austenite, which gives it a combination of the benefits of both ferritic and austenitic stainless steels. Their physical properties are between those of austenitic and ferritic stainless steels but tend to be closer to those of the ferritic and to carbon steel.

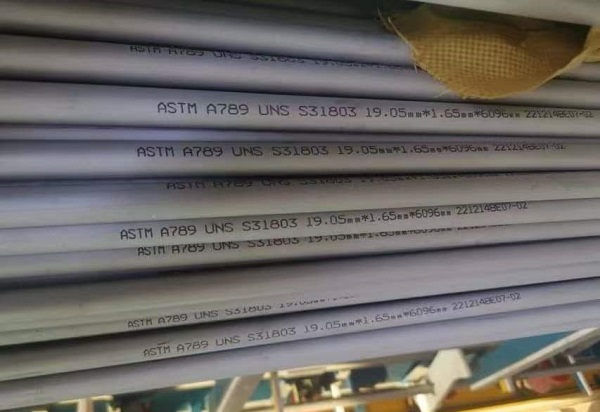

ASTM A789 UNS S31803 seamless tubes, (OD)19.05mm x (WT)1.65mm x (L)6096mm, supplied to Sao Paulo, Brazil.

Compared to 300-series austenitic stainless steels, ASTM A789 grades S31803 and S32205 exhibits better pitting and crevice corrosion resistance, which are a function of chromium, molybdenum, tungsten, and nitrogen content. They have chloride stress corrosion cracking resistance significantly greater than that of the 300-series austenitic stainless steels. They all provide significantly greater strength than the austenitic stainless steels while exhibiting good ductility and toughness.

Both ASTM A789 UNS S31803 and S32205 have the same nominal composition of 22Cr-5Ni-3Mo-N. The composition range set for S31803 was too broad. Experience has shown that for optimum corrosion resistance and to avoid intermetallic phases, the chromium, molybdenum, and nitrogen levels should be kept in the higher half of the ranges for S31803. This modified version with a narrower composition range was introduced with the UNS number S32205. Their chemical composition requirements are presented below, respectively.

ASTM A789 UNS S31803:

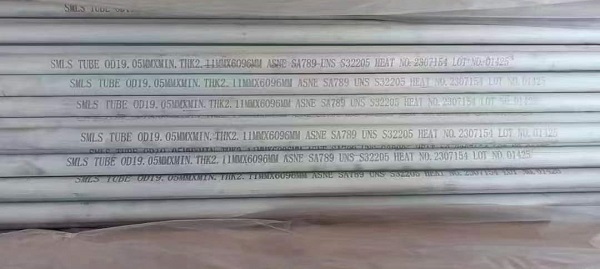

ASTM A789 UNS S32205 seamless tubes for the potassium chloride solution evaporation and concentration reactor. (OD)19.05mm x (min WT)2.11mm x (L)6.096mm, packaged in wooden cases, supplied to Johannesburg, South Africa.

ASTM A789 UNS S32205:

ASTM A789 UNS S31803 Tubes:

ASTM A789 UNS S32205 Tubes:

S32205 has a slightly higher strength compared to S31803, which makes it more suitable for applications requiring enhanced mechanical performance.

ASTM A789 grades S31803 and S32205 tubes shall be made by the seamless or welded process with no filler metal added. The hot forming temperature range in the production process shall be 950-1230°C [1740-2250°F]. After hot forming, it is necessary to perform a full solution anneal followed by a rapid quench to fully restore the mechanical properties and corrosion resistance of the duplex stainless steel tubing. The tubing should be soaking in a temperature ranging from 1020°C [1870°F] to 1100°C[2010°F] for long enough time to dissolve any intermetallic precipitates. The tubing should be subsequently water quenched from the solution annealing temperature. After the heat treatment, these tubes shall be pickled to remove excessive mill scale.

ASTM A789 S32205 seamless tubes are fed into the furnace for solution annealing heat treatment.

The S31803 and S32205 tubes manufactured in accordance with ASTM A789 shall be subjected to the following tests and inspection: visual inspection, dimensional examination, PMI inspection, tension tests, flaring test (for seamless tubes), flange test (for welded tubes), hardness test, X-ray inspection (for welded tubes), hardness test, reverse flattening test (for welded tubes), hydrostatic test, non-destructive test (NDT), pneumatic test (if specified by the purchaser).

The pickling of ASTM A789 duplex 2205 seamless tubes.

ASTM A789 S31803/ S32205 are the workhorse grades which account for nearly 81% of duplex stainless steel tubing use. That’s the reason why they are called standard duplex stainless steels. The Pitting Resistance Equivalent Number (PREN) is a calculated value used to estimate the corrosion resistance of stainless steels, particularly their resistance to pitting corrosion in chloride-containing environments. The formula for calculating PREN is: PREN=%Cr+3.3×%Mo+16×%N. The PREN value for S32205 is typically around 35~36, while that for S31803 is around 34. These PREN values indicate that both UNS S31803 and S32205 tubes have excellent resistance to pitting and crevice corrosion, with S32205 being slightly more resistant due to its higher PREN. This makes them suitable for use in environments where chloride-induced corrosion is a concern, such as in seawater, chemical processing, and oil and gas applications.