Categories

- Technical & Application (25)

- Steel Tubing (21)

- Alloy Tubing (8)

ASTM A213 TP321 seamless tubes are a series of seamless boiler, superheater and heat exchanger tubes made from titanium-stabilized austenitic stainless steel 321. TP321 contains additional titanium to stabilize the carbon, improving its resistance to sensitization (the formation of chromium carbides) and subsequent intergranular corrosion in high-temperature environments. Compared to TP304 tubing, it exhibits improved corrosion resistance at elevated temperatures. Its chemical composition requirements are as follow: (1) Chromium (Cr): 17.0-19.0%, (2) Nickel (Ni): 9.0-12.0%, (3) Titanium (Ti): 5×(C+N) – 0.70%, (4) Carbon (C): maximum 0.08%, (5) Manganese (Mn): maximum 2.0%, (6) Silicon (Si): maximum 1.0%, (7) Phosphorus (P): maximum 0.045%, (8) Sulfur (S): maximum 0.03%.

ASTM A213 TP321 seamless tubes for hydrogen-cracking unit heat exchangers in a chemical plant, bright annealed.

The most noteworthy is that the titanium content added shall be no less than 5 times the sum of carbon and nitrogen content. When steel containing carbon and nitrogen is heated to high temperatures (typically above about 425°C or 800°F), these elements can combine with chromium to form chromium carbides and chromium nitrides. These compounds precipitate at the grain boundaries of the steel, depleting the chromium in the surrounding areas and reducing the steel’s corrosion resistance. By adding a high enough concentration of titanium, it reacts preferentially with carbon and nitrogen to form titanium carbides and nitrides, which are more stable and do not precipitate as readily at grain boundaries. This helps to maintain a higher chromium content in the matrix of TP321 stainless steel, preserving its corrosion resistance.

ASTM A213 TP321 seamless tubes, pickled, supplied to Doha, Qatar.

The typical mechanical properties of ASTM A213 TP321 seamless tubing include: (1) Tensile Strength: minimum 515 MPa (75 ksi); (2) Yield Strength: minimum 205 MPa (30 ksi); (3) Elongation in 2″: minimum 40%; (4) Brinell hardness: maximum 192 HBW, Vickers hardness: maximum 200 HV, Rockwell hardness: maximum 90 HRB.

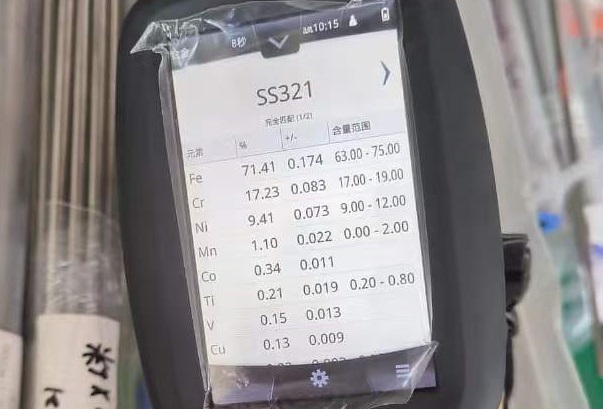

PMI conducted by a handheld microscopic spectrometer on ASTM A213 TP321 tubes.

ASTM A213 TP321 seamless tubes shall be made by the seamless process and shall be either hot finished or cold finished. They shall be solution annealed at a temperature no less than 1900°F [1040°C], followed by a rapid quench. These tubes are usually specified by outside diameter, minimum wall thickness and length. When inserted in a boiler or tube sheet, they shall stand expanding and beading without showing cracks or flaws. TP321 superheater tubes shall stand all forging ,welding, and bending operations necessary for application without developing defects.

Visual inspection, dimensional examination, tensile test, hardness test, PMI test, flattening test, flaring test, hydrostatic test, NDT test.