Metalsin Tech supplies stainless steel TP316L welded tubes for shell-and-tube heat exchangers of gas treaters in rich amine service. Rich amine service involves handling and processing amine solutions that have absorbed acidic gases like hydrogen sulfide (H₂S) and carbon dioxide (CO₂) in gas processing or refining operations. These “rich” amine solutions are typically regenerated by heating to release the absorbed gases, allowing the amine to be reused. This service is crucial in natural gas processing, refineries, and chemical plants to ensure gas purification, with proper material selection and process control necessary to prevent corrosion and maintain operational efficiency.

A natural gas liquid separation plant in Rio Grande, Santa Cruz, Bolivia.

A gas treater in rich amine service is a system used to purify gas streams by removing acidic gases like hydrogen sulfide (H₂S) and carbon dioxide (CO₂) using amine solutions. The process involves an amine absorber, where sour gas is contacted with lean amine, absorbing the acidic gases and forming a rich amine solution. This rich amine is then processed in a regenerator to release the absorbed gases, regenerating the amine for reuse. Gas treaters are crucial in natural gas processing, refining, and chemical manufacturing, ensuring that the treated gas meets safety and environmental standards, while also protecting equipment from corrosion and reducing pollution.

ASTM A249 TP316L welded U-tube bundles for shell-and-tube heat exchangers in rich amine service.

A shell-and-tube heat exchanger of the gas treater in rich amine service is designed to handle the temperature and chemical characteristics of amine solutions that have absorbed acidic gases like hydrogen sulfide (H₂S) and carbon dioxide (CO₂). These exchangers, made with corrosion-resistant materials, recover heat from the rich amine to preheat the lean amine before it enters the regenerator, enhancing energy efficiency and reducing operational costs. This setup is essential in natural gas processing, refineries, and chemical plants for effective gas sweetening, maintaining system efficiency, and protecting equipment from corrosion and thermal stress.

ASTM A249 TP316L U-bend welded tubes for a shell-and-tube heat exchanger.

ASTM A249 TP316L welded tubes are used for shell-and-tube heat exchangers in gas treaters for rich amine service due to their superior corrosion resistance, strength, and durability. As a low-carbon variant of Type 316 stainless steel, TP316L excels in resisting corrosion from acidic components like hydrogen sulfide (H₂S) and carbon dioxide (CO₂) commonly found in amine solutions. Its mechanical properties ensure reliable performance under high-pressure and high-temperature conditions, while its low carbon content prevents intergranular corrosion and facilitates better weldability. These qualities contribute to an extended service life, making TP316L a preferred choice for handling the demanding conditions in gas processing and refining operations.

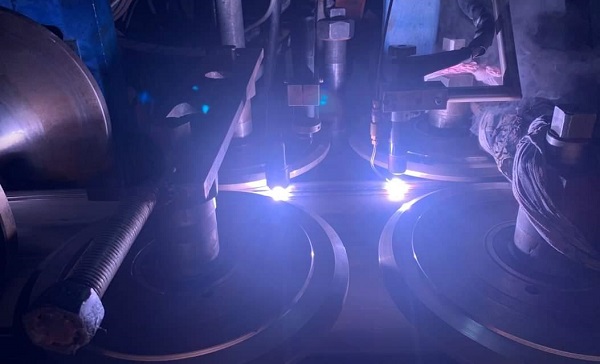

Laser welding process for the production of ASTM A249 stainless steel welded tubes.

According to ASTM A249, TP316L welded tubes shall be made from stainless steel strips by an automatic welding process with no addition of filler metal. Among a series of automatic welding process, laser beam welding or laser welding plays a significant role. Laser-beam welding is a high-precision technique used in fabricating stainless steel welded tubes. “Laser” stands for light amplification by stimulated emission of radiation. Laser welding utilizes a focused laser beam to join metal components, offering key advantages such as exceptional precision, high-strength welds, and minimal heat input, which reduces thermal distortion and preserves the material’s properties. Laser welding ensures enhanced corrosion resistance, clean welds with minimal spatter, and efficient production, making it ideal for maintaining the durability and performance of tubes in harsh conditions.