Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

Hot-dip galvanized seamless square tubes.

HSS (Hollow Structural Sections) tubes are a type of metal profile used primarily in construction and structural applications. These tubes are hollow, with consistent wall thickness throughout, and come in a variety of shapes, such as square, rectangular, circular (round), and elliptical. They are usually made from carbon steel, stainless steel, aluminum, copper, or other materials depending on the specific requirements of the structure in accordance with a series of international standards. HSS tubes, either seamless or welded, are known for their high strength-to-weight ratio, weldability, and uniform shape, making them ideal for structural designs and load-bearing applications. Depending on the material, they may also provide significant corrosion resistance, particularly in stainless or galvanized steel forms.

Hot-dipped-galvanization (HDG) welded rectangular tubes.

HSS (Hollow Structural Sections) tubes are governed by various international standards that ensure material properties, dimensions, and performance consistency across industries. Key standards include ASTM (A500, A554, A1085, A847) in the U.S. for carbon, high-strength steel, and stainless steel tubing, EN (10210, 10219) in Europe for hot and cold-formed sections, JIS (G3466, G3444) in Japan for welded and structural tubes, CSA (G40.20/G40.21, S136) in Canada for construction, ISO (4019, 10799-2) globally for welded and seamless sections, and AS/NZS 1163 in Australia/New Zealand for cold-formed hollow sections.

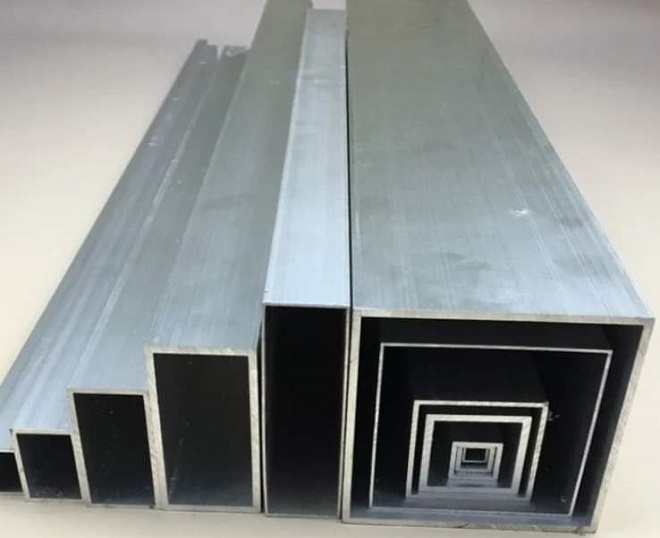

Aluminum tubes in various rectangular and square cross-sections for structural purposes.

Chinese standards for HSS tubes cover both welded and seamless steel sections, focusing on mechanical properties, chemical composition, and dimensional tolerances. Key standards include GB/T 6728 for cold-formed welded sections, GB/T 3094 for cold-drawn shaped tubes, GB/T 178 and GB/T 8162 for seamless steel tubes, and GB/T 12770 for welded stainless steel tubes. Additional standards like GB/T 13793 and GB/T 3091 address welded tubes for fluid conveyance, with specifications also relevant to structural applications. GB/T 11263 covers H-section steel, often used alongside HSS tubes in construction.

HSS aluminum tubes are governed by various international standards that ensure their suitability for structural applications in construction, transportation, and aerospace. Key standards include ASTM B221 for extruded aluminum alloys like 6061 and 6063, ASTM B429 for seamless and welded tubes, and ASTM B241 for aluminum-alloy pipes. European norms such as EN 755-2 and EN 12020-2 outline mechanical properties and dimensional tolerances, while ISO standards like ISO 6362-1 cover wrought aluminum tubes. HSS copper tubes shall be manufactured in accordance with ASTM B447, EN 12449, JIS H3301, JIS 3300, ISO 13349, ISO 1057.