Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

ASTM A249 welded stainless steel tubes are widely used in various industries working as heat exchanger, boiler, superheater, and condenser tubes. Compared to the seamless tubing, these welded stainless steel tubes offer several significant advantages:

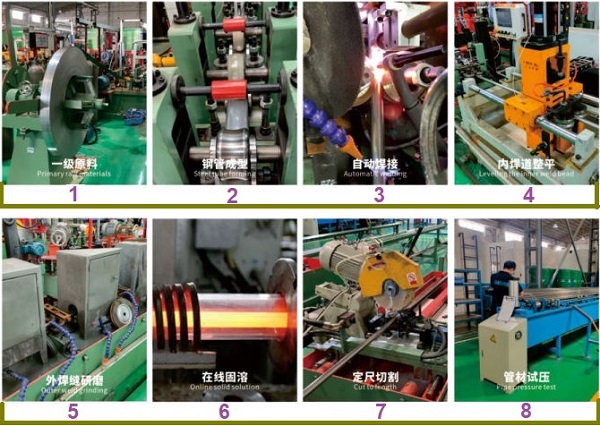

The typical production flowchart for ASTM A249 welded stainless steel tubes.

The manufacturing process for ASTM A249 welded stainless steel tubes is more efficient and less costly compared to seamless tubes made to ASTM A213. As illustrated in above flowchart, the welded tubes shall be made from flat-rolled stainless steel strips by an automatic welding process with no addition of filler metal in a few steps: (1) The coiled stainless steel strip is flattened and fed to the line; (2) The flat strip is rolled into tubular shape for subsequent welding; (3) TIG (GTAW) welding process; (4) The interior weld seam is levelled; (5) The exterior weld seam is ground; (6) Online bright annealing; (7) Precisely sizing and cutting to fixed length; (8) Hydrostatic test. The production process generally results in less material waste, further reducing costs. This makes them a more economical option, especially for large-scale projects.

The ASTM A249 welded stainless steel tubes have a more consistent wall thickness throughout their length due to the controlled manufacturing process. The uniform wall thickness in ASTM A249 welded tubes is vital for ensuring efficient heat transfer, reliable structural integrity, and consistent mechanical performance. It promotes effective thermal conductivity in heat transfer, distributes mechanical stresses evenly to prevent failure, and provides predictable strength and flexibility. Consistent wall thickness enhances the tube’s durability, extends its service life, and simplifies fabrication and installation by ensuring a proper fit with other components.

A shell-and-tube heat exchanger made of ASTM A249 TP316L welded tubes.

Ovality of an ASTM A249 welded tube measures how much its cross-section deviates from a perfect circle, calculated as the difference between the maximum and minimum diameters divided by the nominal diameter, expressed as a percentage. When used as heat exchanger, boiler, superheater, and condenser tubes, the ovality of tubes is crucial because it impacts fluid flow efficiency, heat transfer performance, structural integrity, installation fit, and fluid resistance. Excessive ovality can lead to irregular flow, reduced heat transfer efficiency, increased risk of mechanical failure, alignment issues during installation, and higher pressure drops, all of which affect the overall performance, reliability, and longevity. Because the forming and welding processes of welded tubes occur at relatively lower temperatures, and the thickness and width of the raw materials (stainless steel strips) can be more precisely controlled, the ovality of welded tubes is easier to manage during production. Especially after welding, welded tubes typically undergo cold drawing or sizing processes, which further helps to correct the tube’s ovality to optimal level.