Categories

- Technical & Application (25)

- Steel Tubing (20)

- Alloy Tubing (8)

ASTM A269 TP316/TP316L seamless tubing refers to a specific type of austenitic stainless steel tubing that conforms to the requirements outlined by ASTM A269 standards. TP316 is a type of austenitic stainless steel characterized by its high chromium (16-18%) and nickel (10-14%) content, along with molybdenum (2-3%) for enhanced corrosion resistance, particularly in chloride-containing environments. TP316L is a low-carbon variant of TP316, with a maximum carbon content of 0.03%. The lower carbon content helps minimize carbide precipitation and sensitization during welding, thereby improving corrosion resistance in certain environments, especially in welded structures.

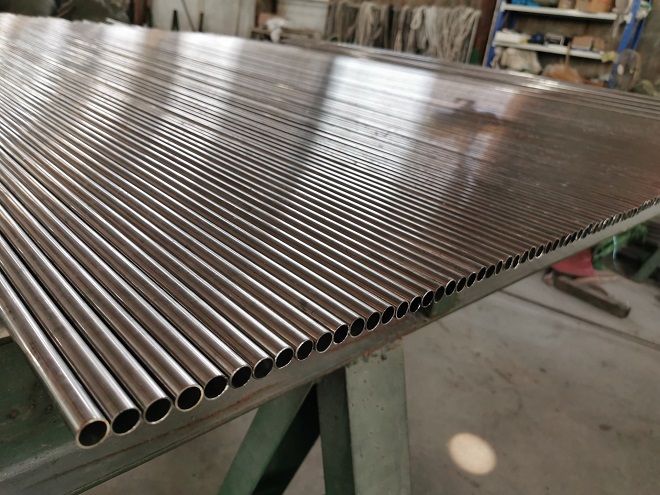

ASTM A269 TP316 seamless tubing, O.D.=12.7mm, W.T.=1.65mm, L=4800mm, supplied to Buenos Aires, Argentina.

Chemical Composition for ASTM A269 TP316/TP316L seamless tubing:

ASTM A269 TP316/TP316L seamless tubing may undergo a bright annealing heat treatment during the production process to achieve specific surface finish and unique mechanical properties. Bright annealing is a specialized heat treatment process aimed at achieving a highly polished surface of stainless steel material while ensuring desired mechanical properties and corrosion resistance. Prior to heat treatment, it’s essential to ensure the cleanliness of the tube surface. The tube is heated to a temperature range of 1900°F to 2100°F (1038°C to 1149°C) to ensure uniform heating. Once the target temperature is reached, the material is held for a certain period to ensure uniform internal temperature, allowing for grain recrystallization and residual stress relief. After the holding period, the tube needs to be rapidly cooled to room temperature. Bright annealing heat treatment may have certain effects on the dimensions and shape of the tubing, so careful consideration and planning are necessary before conducting this process.

“General service” refers to a broad range of applications and environments where TP316/316L tubing is utilized for various purposes that do not require highly specialized or extreme conditions. The term encompasses a wide array of industries and applications where corrosion resistance, durability, and general performance are essential but do not involve specific, highly demanding conditions. Examples of general service applications for stainless steel tubing include: